In the world of manufacturing, titanium 3D printing is like the superhero no one saw coming. Forget the days of heavy machinery and tedious processes. Now, with a flick of a printer button, engineers can create lightweight, strong structures that even Iron Man would envy. Imagine crafting complex parts that are not only durable but also resistant to corrosion. It’s like giving your designs a titanium boost, literally!

Table of Contents

ToggleOverview of Titanium 3D Printing

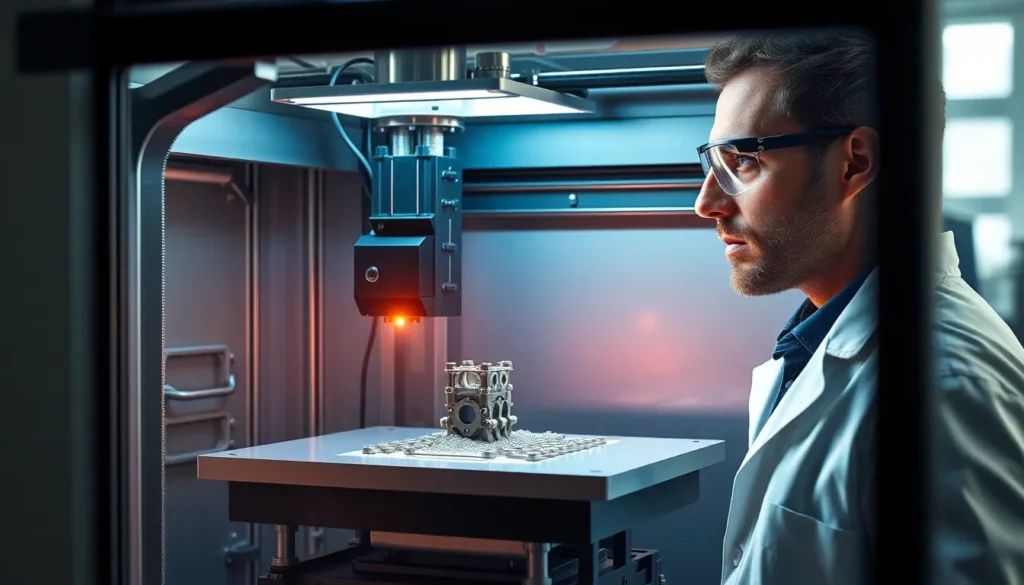

Titanium 3D printing represents a significant advancement in additive manufacturing. This technique allows for the creation of complex geometries that traditional manufacturing methods can’t achieve. Engineers utilize titanium’s lightweight yet robust properties to enhance design possibilities.

Additive manufacturing techniques, like selective laser melting (SLM) and electron beam melting (EBM), play a crucial role. These methods enable precise layer-by-layer construction, optimizing material usage and reducing waste. Each layer of titanium powder melts and fuses, establishing a strong bond that results in a durable final product.

Industries such as aerospace, biomedical, and automotive benefit immensely from this technology. In aerospace, companies produce intricate components that meet stringent weight and strength requirements. Biomedical applications often include custom implants tailored to specific patient needs, improving surgical outcomes and recovery times.

Corrosion resistance signifies another critical advantage of titanium. It performs exceptionally well in harsh environments, maintaining integrity and functionality over time. Engineers appreciate how this enhances longevity and safety in applications ranging from marine components to chemical processing equipment.

Cost considerations arise with titanium 3D printing. While initial expenses may vary, the reduction in material waste and the ability to create lightweight components can lead to lower overall production costs in many cases. Additionally, improved lead times for prototypes and final parts contribute to quicker project timelines.

Understanding the benefits and limitations of titanium 3D printing assists manufacturers in making informed decisions. It fosters innovation while addressing production challenges, highlighting how this technology revolutionizes the manufacturing landscape.

Benefits of Titanium 3D Printing

Titanium 3D printing offers numerous advantages, making it an appealing choice for various industries. Notable benefits include its lightweight strength and exceptional corrosion resistance.

Lightweight Strength

Titanium’s high strength-to-weight ratio is a significant advantage in many applications. Engineers favor this property when designing components that require strength without added weight. Aerospace vehicles use titanium parts to improve fuel efficiency and performance. In the automotive sector, technicians achieve lighter structures, enhancing speed and agility. When creating complex geometries, titanium maintains strength without compromising structural integrity. The ability to manufacture intricate designs allows for innovative solutions in various fields, including biomedical implants and performance machinery.

Corrosion Resistance

Titanium’s inherent corrosion resistance is another standout benefit that ensures longevity in challenging environments. This characteristic makes titanium highly suitable for applications exposed to harsh conditions, such as marine and chemical industries. Equipment and components made from titanium require less maintenance due to their resistance to saltwater and other corrosive agents. In medical applications, titanium implants avoid corrosion and tissue reactions, promoting better patient outcomes. Manufacturers find that utilizing titanium improves durability, leading to longer lifecycles for critical components.

Applications of Titanium 3D Printing

Titanium 3D printing finds extensive applications across various industries, altering traditional manufacturing practices and driving innovation.

Aerospace Industry

Aerospace companies utilize titanium 3D printing to manufacture lightweight components that enhance fuel efficiency. Parts such as brackets and engine components benefit from titanium’s strength-to-weight ratio. Combine durability with intricate designs for optimized aerodynamics. Leading manufacturers, like Boeing and Airbus, embrace this technology to produce high-performance parts that meet rigorous safety standards. The ability to print complex geometries reduces assembly time and lowers production costs, making titanium an essential material in the aerospace sector.

Medical Implants

The medical field employs titanium 3D printing for creating custom implants tailored to patient anatomy. Surgeons use titanium implants for their biocompatibility and resistance to corrosion. Personalized orthopedic devices and dental implants improve surgical outcomes and patient satisfaction. Techniques like electron beam melting enable precise engineering of structures that closely mimic natural bone._custom specifications lead to better fitting and faster healing, maximizing efficacy and ensuring longevity in medical applications.

Automotive Sector

In the automotive sector, manufacturers rely on titanium 3D printing to produce lightweight, durable components that enhance vehicle performance. Parts such as exhaust systems and connecting rods significantly benefit from titanium’s properties. Using this technology allows for innovative designs that increase performance while reducing weight, contributing to overall fuel efficiency. Companies like Ford and Porsche incorporate titanium components in high-performance models for better acceleration and handling. The reduction in material waste further makes titanium an economically viable option for automotive applications.

Challenges in Titanium 3D Printing

Titanium 3D printing faces several challenges that can impact its widespread adoption. Key areas of concern include cost factors and material limitations.

Cost Factors

Initial investment costs for titanium 3D printing equipment often remain high. Process expenses accumulate quickly due to factors like machine maintenance and specialized materials. Additionally, the complexity of titanium alloy production can further increase prices. While long-term savings emerge from reduced waste and quicker production times, many industries hesitate to embrace this technology due to upfront financial barriers. The need for skilled operators also contributes to overall costs, making training a vital element in ensuring successful implementation.

Material Limitations

Material limitations in titanium 3D printing hinder some applications. Specific titanium alloys may not exhibit the desired mechanical properties under certain conditions. Variability in powder quality can lead to inconsistent print results, affecting strength and durability. Moreover, certain geometries might not adhere properly or could warp during printing, complicating the production process. These limitations necessitate ongoing research and development to enhance material performance and expand application possibilities.

Future Trends in Titanium 3D Printing

Titanium 3D printing is set to evolve significantly, driven by ongoing innovations and increased market demand. Technological advancements will further enhance the effectiveness of additive manufacturing processes.

Technological Advancements

New methods in titanium 3D printing, such as hybrid manufacturing systems, combine traditional machining with additive techniques. These systems improve production efficiency while maintaining high precision. Innovations in powder metallurgy are enabling the production of higher-quality titanium alloys, enhancing mechanical properties for specialized applications. Machine learning integration allows for real-time monitoring and optimization of the printing process, reducing material waste. Advancements in post-processing techniques can accelerate production rates, leading to quicker turnaround times for complex components. Emerging technologies, like digital twins, offer simulations to optimize design and manufacturing processes, ensuring better performance of titanium parts in various applications.

Market Growth Predictions

Market analysts anticipate a robust growth trajectory for titanium 3D printing, projecting a compound annual growth rate (CAGR) of over 20% in the coming years. Increased demand in aerospace, medical, and automotive sectors significantly contributes to this growth. As industries seek lightweight and corrosion-resistant materials, titanium’s unique properties make it a top choice. The need for custom solutions and complex geometries drives further expansion, with companies investing heavily in research and development to overcome existing challenges. By 2028, the global titanium 3D printing market could exceed $1 billion, showcasing its critical role in shaping the future of manufacturing.

Titanium 3D printing is redefining manufacturing processes across various industries. Its ability to create complex geometries and lightweight structures positions it as a game changer. The advantages of titanium, including durability and corrosion resistance, further enhance its appeal in sectors like aerospace and medical.

As technology advances and challenges are addressed, the potential for titanium 3D printing continues to grow. Innovations in production methods and materials promise to expand its applications and improve efficiency. With a significant market growth forecast, titanium 3D printing is set to play a vital role in the future of manufacturing.