In a world where everything seems to be going digital, laser 3D printing is the superhero we’ve all been waiting for. Imagine a machine that can transform a digital design into a tangible object faster than you can say “Where’s my coffee?” This cutting-edge technology is not just a flashy gimmick; it’s revolutionizing industries from aerospace to healthcare, proving that the future of manufacturing is here, and it’s got a laser focus.

Laser 3D printing takes creativity to new heights, allowing designers to push boundaries and create complex shapes that traditional methods can only dream of. It’s like having a magic wand that turns ideas into reality—minus the fairy dust. Whether it’s crafting custom prosthetics or creating intricate prototypes, this technology is changing the game. Buckle up as we dive deeper into the world of laser 3D printing and discover how it’s shaping our future, one layer at a time.

Table of Contents

ToggleOverview of Laser 3D Printing

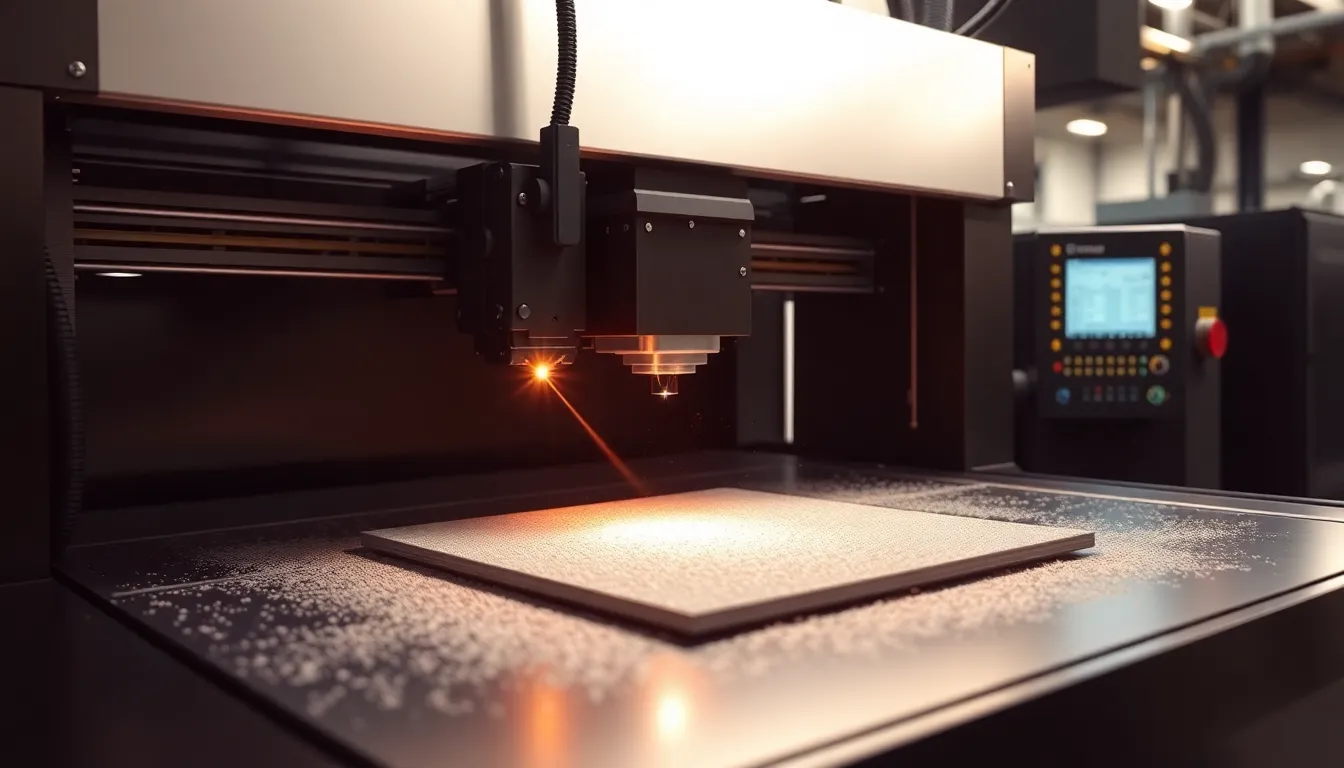

Laser 3D printing utilizes focused laser beams to fuse materials into solid objects. This technology primarily employs methods such as selective laser sintering (SLS) and selective laser melting (SLM). SLS involves the use of powdered materials that lasers precisely heat, allowing them to bond together.

In various industries, laser 3D printing offers significant advantages. The aerospace sector benefits from lightweight components manufactured with intricate geometries. Precision in healthcare allows for customized prosthetics and implants tailored to individual patients’ needs.

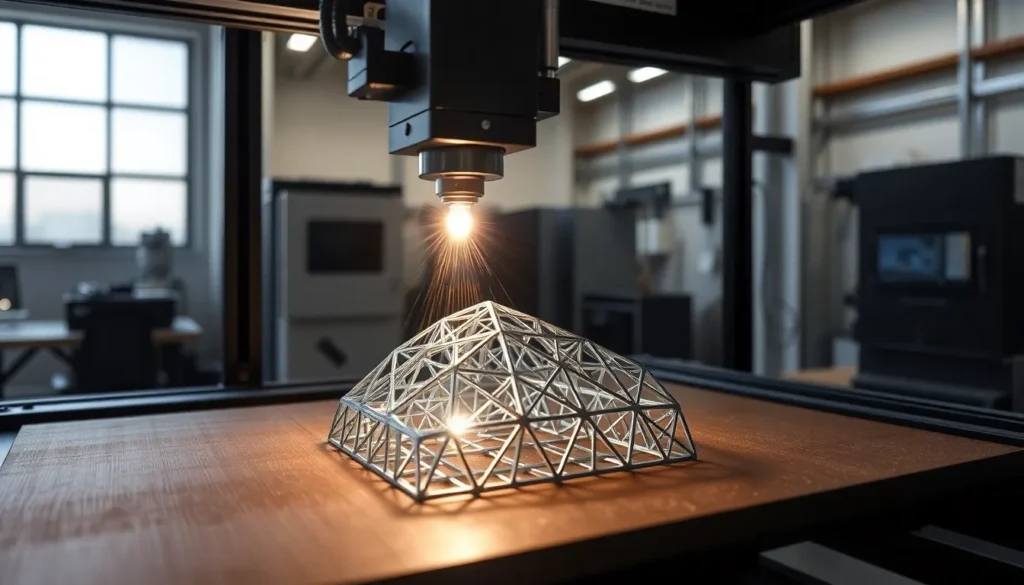

Complex shapes, which traditional manufacturing methods struggle to produce, become achievable with laser 3D printing. Designers gain the freedom to innovate beyond the constraints of subtractive manufacturing processes. Additive manufacturing enables the creation of intricate lattice structures that reduce weight without sacrificing strength.

Materials used in laser 3D printing include metals, polymers, and ceramics. Each material presents unique properties and applications. For example, titanium’s strength makes it ideal for aerospace components, while polymers are prevalent in consumer products.

Cost-effectiveness also emerges as a notable benefit. Reduced material waste and the ability to produce prototypes quickly lower production costs. Companies can assess designs faster, leading to shorter product development cycles.

Laser 3D printing continues to evolve with advancements in technology. Innovations in laser techniques and improved materials enhance efficiency and expand applications. With ongoing exploration, this technology remains pivotal in shaping the future of manufacturing.

How Laser 3D Printing Works

Laser 3D printing operates through advanced technologies that transform digital designs into tangible objects. This process utilizes precise laser beams to manipulate materials, solidifying them layer by layer.

Process Overview

Layer-by-layer construction defines the laser 3D printing process. It begins with a digital design, often produced using computer-aided design (CAD) software. A thin layer of material, such as powdered metal or polymer, is spread across the build platform. Focused laser beams target specific areas, fusing the particles. Each new layer builds on the previous one, allowing for the creation of highly detailed structures. Cooling and solidification occur after each layer, ensuring stability. This method minimizes waste while achieving rapid prototyping and production, catering to demands in various industries.

Key Technologies Involved

Several key technologies drive laser 3D printing. Selective laser sintering (SLS) involves fusing powdered materials without complete melting, optimizing strength and detail. Selective laser melting (SLM) fully melts material, resulting in fully dense and robust components. Another notable method is laser metal deposition (LMD), which adds material onto existing structures for repairs or enhancements. Each technology caters to different materials and applications, providing flexibility and innovation. Together, these methods create opportunities for custom designs across fields, including aerospace and healthcare, further advancing manufacturing capabilities.

Applications of Laser 3D Printing

Laser 3D printing plays a crucial role across various sectors by enabling precise fabrication and innovative designs.

Industrial Uses

Manufacturers heavily rely on laser 3D printing for producing lightweight yet durable components. Aerospace companies benefit from reduced weight without compromising strength, which improves fuel efficiency. Automotive industries utilize this technology for prototyping and creating complex parts that streamline assembly. Rapid prototyping within these sectors accelerates product development, allowing companies to bring innovations to market more efficiently. Additionally, custom tooling and production aids save time and resources, enhancing overall manufacturing capabilities.

Medical Innovations

Healthcare professionals embrace laser 3D printing to create individualized medical solutions. Customized prosthetics and implants fit patients more comfortably, offering improved functionality. Surgeons use this technology to produce intricate anatomical models for pre-operative planning, enhancing surgical precision. Moreover, dental fields leverage laser 3D printing to fabricate crowns and dentures tailored to specific patient needs. As this technology evolves, its contributions to regenerative medicine and bioprinting show promising potential for creating tissues and organs.

Advantages of Laser 3D Printing

Laser 3D printing offers numerous advantages that enhance manufacturing efficiency and product quality. The technology’s key strengths lie in precision, detail, and material versatility.

Precision and Detail

Precision remains a hallmark of laser 3D printing. It allows for intricate designs that traditional methods struggle to replicate. Each layer gets precisely fused by intense laser beams, resulting in sharply defined features. Complex geometries, like lattices, can be manufactured with exceptional accuracy. Industries that require high tolerance levels, such as aerospace and biomedical fields, benefit notably from this ability. This level of craftsmanship improves product performance and often leads to innovations in design.

Material Versatility

Material versatility plays a crucial role in the effectiveness of laser 3D printing. Various materials, including metals, polymers, and ceramics, can be processed to address specific requirements. Each material has distinct properties tailored for different applications. For example, titanium proves advantageous in aerospace due to its strength-to-weight ratio. Plastics offer flexibility for prototyping and consumer products. Ceramics provide durability for dental and medical applications. Manufacturers gain the freedom to choose materials that best meet their functional and aesthetic needs, enhancing creativity while optimizing performance.

Challenges and Limitations

Laser 3D printing faces various challenges and limitations that impact its widespread adoption and efficiency.

Cost Considerations

Expensive equipment and materials contribute to the initial costs of laser 3D printing. Organizations often wrestle with high upfront investments, which can create barriers for small businesses. Moreover, ongoing maintenance requirements for the sophisticated machinery add to operational expenses. Material costs also fluctuate, with metals like titanium and complex polymers often commanding premium prices. The necessity for skilled operators to ensure proper setup and operation heightens overall training costs. As companies evaluate budgets, these financial factors require careful consideration.

Technical Challenges

Laser 3D printing involves intricate technical challenges that can hinder production. Limited build size affects the dimensions of objects that can be printed, posing restrictions for large-scale projects. Variability in laser power impacts the consistency and quality of finished products, which might lead to defects or failed prints. Additionally, material compatibility can restrict the types of parts produced, necessitating experimentation with different settings and combinations. Complex geometries sometimes lead to difficulties in achieving desired results, requiring additional design adjustments. Addressing these technical hurdles remains essential for enhancing efficiency and reliability.