In a world where everything seems to be getting faster, why should manufacturing be any different? Enter industrial 3D printing, the superhero of the production line. This technology isn’t just about creating cool toys or funky prototypes; it’s revolutionizing industries from aerospace to healthcare. Imagine printing a jet engine or a custom prosthetic limb—all while sipping your morning coffee.

Table of Contents

ToggleOverview of Industrial 3D Printing Applications

Industrial 3D printing significantly influences various sectors by streamlining production processes and reducing costs. Aerospace companies utilize this technology to create lightweight components, enhancing fuel efficiency and performance. Automotive manufacturers apply 3D printing for rapid prototyping and tooling, accelerating the development of new models.

Healthcare benefits from 3D printing through customized implants and surgical tools. Surgeons can rely on patient-specific models, improving surgical outcomes and reducing recovery times. In addition, the construction industry leverages 3D printing to produce complex structures, minimizing material waste and labor costs.

Consumer goods production sees a transformation with 3D printing, allowing businesses to swiftly respond to market trends. Customization is now readily available for items such as footwear and electronics. Furthermore, the energy sector employs this technology for creating durable and efficient components.

Education and research institutions adopt 3D printing for innovative projects, enabling students to explore advanced design and manufacturing techniques. This hands-on approach fosters creativity and problem-solving skills across disciplines.

Logistics and supply chain management benefit from on-demand 3D printing, reducing inventory costs and lead times. Businesses can produce parts when needed, ensuring they meet customer demands effectively.

All these examples demonstrate how industrial 3D printing applications enhance productivity and innovation across numerous fields.

Key Industries Utilizing 3D Printing

Industrial 3D printing finds application in numerous key industries, driving innovation and efficiency.

Aerospace and Defense

Aerospace companies leverage 3D printing to produce lightweight components that contribute to enhanced fuel efficiency. Complex geometries, often challenging to manufacture through traditional methods, become possible with this technology. Military applications benefit from rapid prototyping of parts, allowing for quicker deployment of new technologies. Additionally, 3D printing enables on-demand manufacturing of spare parts, which reduces logistical challenges and leads to a more responsive supply chain. By utilizing advanced materials, aerospace firms can create components that withstand extreme conditions, ensuring reliability in flight and defense scenarios.

Automotive

Automotive manufacturers utilize 3D printing to accelerate prototyping and tooling processes, enabling faster design iterations. Customized parts, tailored for specific vehicle models, are developed more efficiently using this approach. The technology also supports lightweight component production, leading to improved fuel efficiency. By reducing the number of components in assemblies, 3D printing simplifies designs, thus enhancing performance and reducing costs. Additionally, companies can quickly produce low-volume production runs, responding to consumer trends and demands more effectively.

Healthcare

In healthcare, 3D printing revolutionizes the production of customized implants and surgical tools. Personalized prosthetics, designed to fit individual patients, improve comfort and functionality. Surgical models crafted from patient-specific data allow for enhanced pre-surgery planning, leading to better outcomes. The technology also streamlines the creation of complex medical devices, which can be manufactured at lower costs and with higher precision. By enabling on-demand production of medical supplies, 3D printing addresses immediate patient needs and reduces lead times for critical equipment.

Types of 3D Printing Technologies

Industrial 3D printing encompasses various technologies, each suited for different applications and materials.

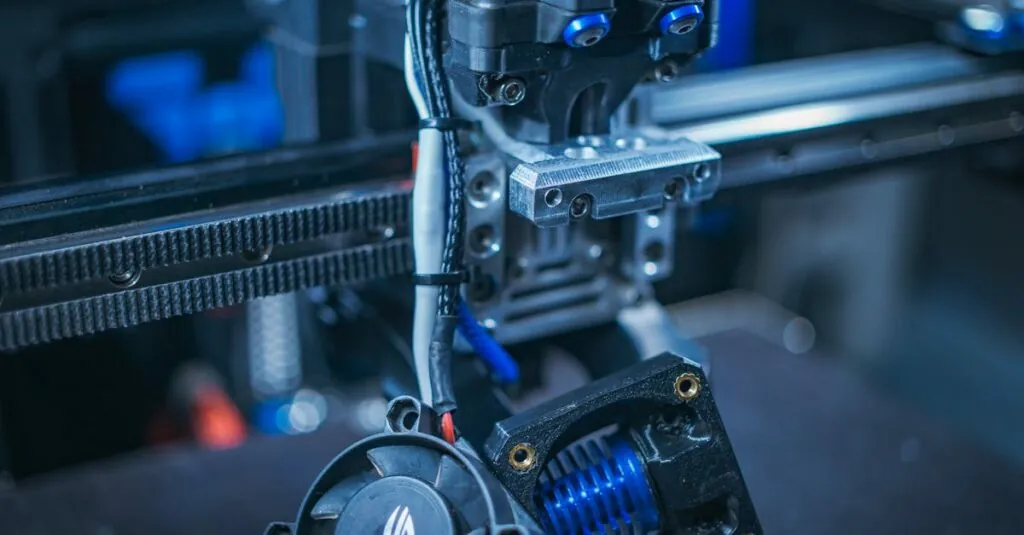

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) ranks among the most common 3D printing methods. This technology uses thermoplastic filaments that are heated and extruded layer by layer to create objects. Often employed for prototyping, FDM provides the ability to produce durable parts quickly. Industries such as automotive and consumer goods frequently utilize FDM due to its cost-effectiveness. It’s also accessible, making it popular in educational settings for teaching and experimentation. Another advantage includes a wide range of materials, allowing for versatility in design and functionality.

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) operates by using a laser to fuse powdered materials, forming solid structures. This method excels in producing complex geometries, making it ideal for applications in aerospace and healthcare. SLS allows for the creation of lightweight parts that maintain strength, essential in demanding environments. Parts printed using SLS often require minimal post-processing, improving efficiency. Industries benefit from the material options available, such as nylon and metal powders, which contribute to a range of functional prototypes and end-use products. Furthermore, SLS enables full-color printing, enhancing visual appeal for custom items.

Benefits of Industrial 3D Printing

Industrial 3D printing offers numerous advantages that enhance manufacturing processes. These benefits extend across various industries, facilitating innovation and efficiency.

Cost Efficiency

Cost efficiency stands as a significant advantage of industrial 3D printing. This technology reduces the need for expensive tooling typically associated with traditional manufacturing methods. By minimizing material waste, production costs decrease while allowing for on-demand production that eliminates excess inventory. Factories can produce components at a lower cost per unit, especially for small batch sizes. With 3D printing, prototypes can be tested cheaply before mass production begins, reducing financial risks for manufacturers.

Design Flexibility

Design flexibility plays a crucial role in industrial 3D printing applications. Manufacturers can create complex geometries and intricate designs that traditional methods struggle to achieve. Rapid prototyping allows for quick iterations, enabling engineers to tweak designs with ease. With this technology, customization becomes straightforward, addressing specific customer needs and enhancing user experience. Industries utilize 3D printing to produce tailored components, which lead to improved products and more creative solutions.

Reduced Waste

Reduced waste is another key benefit of industrial 3D printing. This method generates minimal excess material compared to conventional subtractive manufacturing processes. Material efficiency reduces environmental impact while lowering costs. By using only the necessary amount of materials for each product, manufacturers align with sustainability goals. Overall, the ability to recycle materials in many 3D printing processes further contributes to less waste, making it an eco-friendly manufacturing option.

Challenges in Adoption

Adopting industrial 3D printing presents several challenges that organizations must navigate.

Material Limitations

Material constraints significantly affect the adoption of 3D printing in industrial settings. Many available materials lack the necessary properties for specific applications, limiting their use in high-performance components. While polymers and certain metals are prevalent, industries often require materials with superior strength, durability, or temperature resistance. Despite advances in material science, suitable options remain limited, which affects the overall viability of 3D printing for critical applications. A company intending to enter aerospace might find inadequate material choices for lightweight structures. Hence, ongoing development in materials is crucial for expanding the range of industrial applications.

Regulatory Hurdles

Regulatory challenges also impede the widespread use of industrial 3D printing. Compliance with industry standards and safety regulations poses obstacles for manufacturers looking to integrate the technology. In sectors like aerospace and healthcare, meeting rigorous certification processes is essential and often time-consuming. These sectors demand thorough documentation and validation of 3D printed parts to ensure safety and performance. Companies seeking to innovate may experience delays due to extensive testing requirements. Consequently, regulatory bodies need to adapt existing frameworks to accommodate emerging technologies and facilitate smoother adoption.

Future Trends in Industrial 3D Printing

Industrial 3D printing continues to evolve, with new trends shaping its future landscape.

Advancements in Materials

Innovative materials are emerging for industrial 3D printing. Developments in metal alloys and bio-based polymers enhance performance and sustainability. For instance, titanium alloys are gaining traction in aerospace applications due to their lightweight and strength properties. In healthcare, biocompatible materials enable the production of safer custom implants. The introduction of composites enhances durability and opens new opportunities for complex designs. These advancements contribute to more versatile applications across various industries, showcasing the potential for increased functionality and reduced material waste.

Integration with Automation

Automation increasingly complements 3D printing processes. Automated systems streamline production, minimizing human error and improving efficiency. Robotics integrated into workflows accelerate component handling and quality control. Additionally, smart sensors monitor the printing environment, ensuring optimal conditions for each run. Such synergies allow manufacturers to produce more parts in less time while maintaining high standards. This integration presents possibilities for scalable production, responding to market demand rapidly and effectively. Advanced software solutions also facilitate seamless collaboration between design and manufacturing, enhancing overall productivity.

Industrial 3D printing stands at the forefront of innovation across multiple sectors. Its ability to produce complex, customized components significantly enhances efficiency and reduces costs. As industries continue to embrace this technology, the potential for improved designs and sustainable practices grows.

The integration of advanced materials and automation will likely shape the future landscape of manufacturing. By overcoming existing challenges such as material limitations and regulatory hurdles, industrial 3D printing can unlock new possibilities, driving productivity and creativity.

With ongoing advancements, the technology is poised to redefine traditional manufacturing methods, ensuring its vital role in shaping the future of various industries.