In a world where everything seems to be going digital, 3D printing platforms are turning imagination into reality—literally. Gone are the days of sketching ideas on napkins or dreaming of a perfect gadget. With just a few clicks, anyone can create intricate designs that leap off the screen and into their hands. It’s like having a magic wand, but without the risk of turning your cat into a teapot.

Table of Contents

ToggleOverview of 3D Printing Platforms

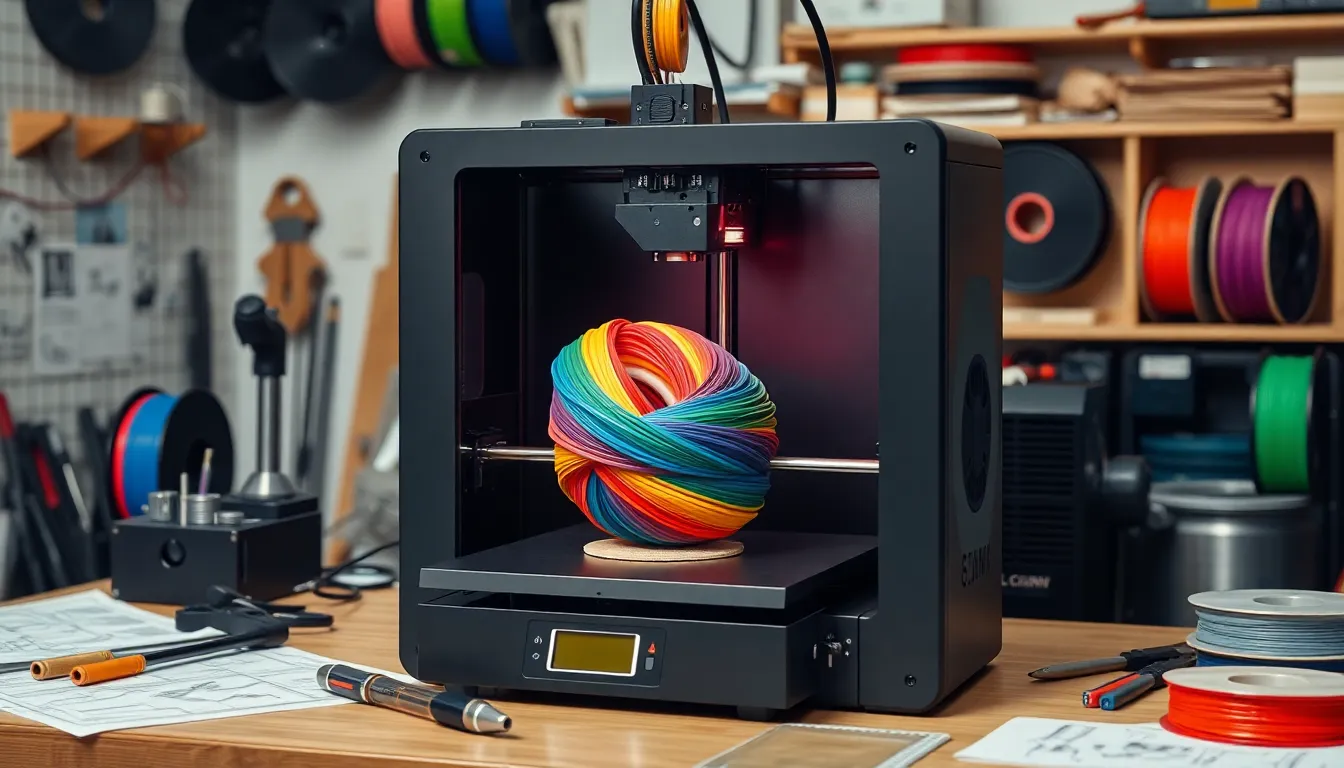

3D printing platforms serve as essential tools for transforming digital designs into physical objects. These platforms offer user-friendly interfaces that simplify the printing process, allowing anyone to create intricate models with minimal effort. Numerous options exist in the market, catering to various needs ranging from hobbyists to professionals.

Popular platforms include Ultimaker Cura, Simplify3D, and PrusaSlicer. Each platform provides unique features, enabling users to optimize their printing settings for better results. Ultimaker Cura excels in versatility and compatibility with multiple printers, while Simplify3D offers advanced features suited for professional-grade prints.

Customization stands out as a critical aspect of these platforms. Users can manipulate settings such as layer height, print speed, and support structure, tailoring the output to specific requirements. Factors like material type and desired finish also play significant roles in the customization process, influencing the final product’s appearance and functionality.

Community support enhances the experience with these platforms, as many have forums and resources for troubleshooting and sharing tips. Users readily contribute tutorials and modifications, facilitating skill enhancement and problem-solving. This collaborative spirit fosters innovation within the 3D printing community.

Compatibility with different printers further underscores the importance of choosing the right platform. Many platforms support a wide array of 3D printer models, ensuring flexibility for users. Compatibility checks and user feedback help streamline the selection process, guiding individuals toward platforms that best suit their hardware.

Ultimately, understanding these aspects empowers users to maximize their 3D printing journeys, transforming ideas into tangible realities.

Types of 3D Printing Platforms

Various types of 3D printing platforms cater to different technological needs and applications. Each platform brings unique benefits and capabilities to the table.

FDM (Fused Deposition Modeling)

Fused Deposition Modeling stands as one of the most common 3D printing methods. This process extrudes thermoplastic filament through a heated nozzle, layering material to build objects from the ground up. High versatility allows users to choose from a wide selection of filaments, including PLA, ABS, and PETG. Affordable and accessible, FDM printers suit hobbyists and educational settings. Users appreciate the straightforward operation and minimal post-processing requirements. Reliability in producing functional prototypes contributes to its popularity among engineers and designers.

SLA (Stereolithography)

Stereolithography utilizes a laser to cure resin layer by layer, creating highly detailed models. This technique excels in producing intricate designs with smooth finishes. It works well for dental applications, jewelry, and quick prototyping. Resins suited for SLA come in various formulations, allowing for customization based on properties such as flexibility and transparency. The ability to produce finer details makes SLA printers preferable for precision tasks. Users often find the post-processing more involved due to the need for rinsing and curing.

SLS (Selective Laser Sintering)

Selective Laser Sintering employs a laser to fuse powdered material, typically nylon or polyamide, into solid parts. This method enables the production of complex geometries without support structures. Strong and functional parts emerge from the process, making it ideal for industrial applications and end-use parts. Variety in materials enhances SLS’s capabilities, offering options like glass-filled nylon and elastomers. Consideration of cost is crucial, as SLS printers and materials can be more expensive than FDM or SLA counterparts. Users benefit from the ability to create lightweight yet durable designs.

Popular 3D Printing Platforms

Several 3D printing platforms stand out in the industry, each offering unique functionalities to support users’ creative processes.

Ultimaker Cura

Ultimaker Cura serves as a leading slicing software, designed to streamline the 3D printing experience. Users appreciate its user-friendly interface, which allows easy navigation for beginners and advanced users alike. It supports a wide array of file types, enabling seamless integration with numerous 3D printers. Customization options also abound, permitting modifications to print speed and layer height for optimal results. Community contributions enhance the platform, providing tailored profiles for diverse materials. Regular updates ensure compatibility with the latest advancements in 3D printing technology, making it a favorite among enthusiasts.

Simplify3D

Simplify3D stands out for its powerful slicing engine and extensive feature set. Professionals often choose this platform for its advanced support generation and robust print simulation tools, allowing users to anticipate print issues before they occur. The software offers a comprehensive library of printer profiles, accommodating many printer brands and models. Users can fine-tune settings at a granular level, adapting to specific project requirements. Additionally, the intuitive interface simplifies extensive parameter adjustments, making it accessible despite its advanced capabilities. Online forums further enrich user experience, providing insights and sharing successful print techniques.

PrusaSlicer

PrusaSlicer excels as an open-source software that generates high-quality prints with minimal effort. Developed by Prusa Research, this platform is optimized for Prusa printers but accommodates various other brands. Printing profiles come predefined, facilitating a quick setup for different filament types. Users appreciate the detailed settings available for adjusting infill, support, and speeds, tailoring each print to project needs. Also, the active development community ensures consistent updates that introduce new features and enhance usability. Access to a wealth of online resources helps users troubleshoot and share best practices, reinforcing its popularity within the 3D printing community.

Factors to Consider When Choosing a 3D Printing Platform

Selecting a 3D printing platform involves several critical factors that influence the overall user experience and final output quality.

Cost

Cost affects the choice of a 3D printing platform significantly. Budget constraints can lead users to favor free platforms with basic features. Paid options often provide advanced capabilities and better support, making them suitable for professionals. Users should evaluate the total expenses, including potential subscription fees and material costs. For instance, while platforms like Ultimaker Cura are free, others like Simplify3D may charge around $150, balancing budget against needed features.

Ease of Use

Ease of use plays an essential role in platform selection. Some platforms boast intuitive interfaces that simplify the design process, making them ideal for beginners. Users prefer a platform offering straightforward navigation and clear documentation. Experienced users, however, may seek platforms with advanced features that allow for detailed customization. A platform like PrusaSlicer, known for its ease of use, caters to a broad range of users while offering robust functionalities for those with more experience.

Material Compatibility

Material compatibility serves as a vital consideration when choosing a platform. Selecting a platform that supports the specific materials users plan to print with ensures optimal results. Some platforms specialize in Fused Deposition Modeling (FDM) materials, while others embrace a broader range, including resin and nylon for Stereolithography (SLA) or Selective Laser Sintering (SLS). Users should confirm that their chosen platform accommodates their printer’s supported materials and desired application, empowering them to achieve the best possible outcomes.

3D printing platforms are revolutionizing how individuals and businesses approach creativity and production. With user-friendly interfaces and a wealth of customization options these tools empower users to bring their ideas to life effortlessly. The variety of platforms available caters to diverse needs from hobbyists to professionals ensuring that everyone can find the right fit for their projects.

Community support enhances the experience further providing valuable resources and fostering collaboration among users. As technology continues to evolve the possibilities within the 3D printing landscape are boundless. Embracing these platforms not only unlocks creativity but also opens doors to innovation and practical applications across various industries.